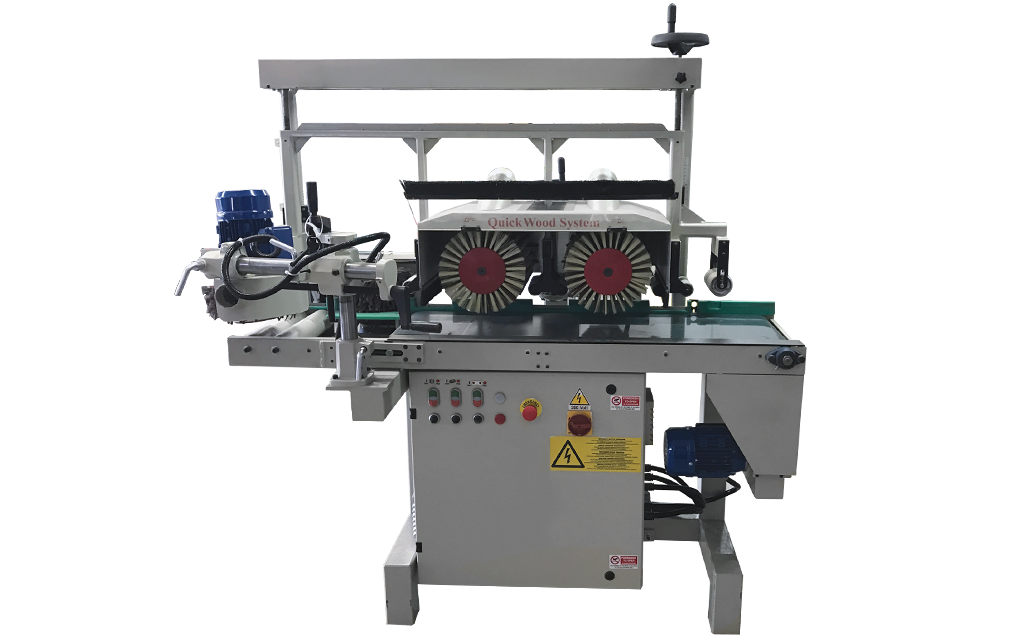

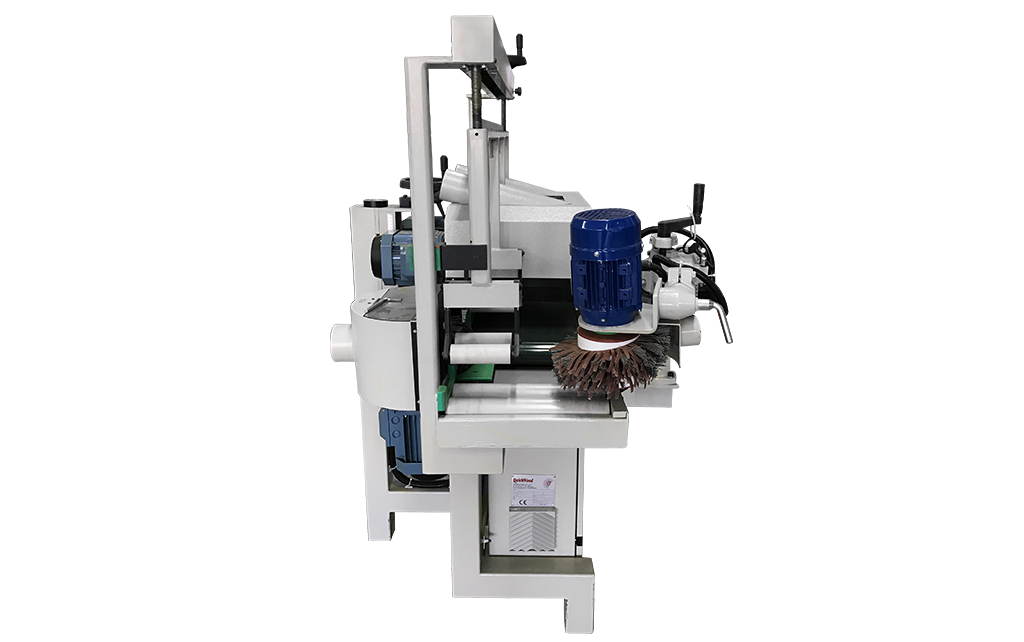

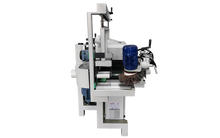

CD2-300 - Molding Sander

Automatic Molding Sander.

MULTIPLE HEAD MOLDING/LINEAR SANDER 12" WIDE

CD2’s are designed to thoroughly and uniformly finish sand and sealer sand work pieces such as moldings, trim and flooring.

The QuickWood CD2 Series Molding sanders have two or more horizontal top spindles and can have two or more vertical side spindles and/or two or more horizontal bottom spindles to sand the various surfaces...

Free Shipping USA

on all orders over $75

Free Shipping Europe

on all orders over $500

Free Shipping Middle East

on all orders over $1000

Automatic Molding Sander.

MULTIPLE HEAD MOLDING/LINEAR SANDER 12" WIDE

CD2’s are designed to thoroughly and uniformly finish sand and sealer sand work pieces such as moldings, trim and flooring.

The QuickWood CD2 Series Molding sanders have two or more horizontal top spindles and can have two or more vertical side spindles and/or two or more horizontal bottom spindles to sand the various surfaces of the work pieces as needed.

All spindles are adjustable for different product sizes as well as abrasive wear. The top and side spindles are tilt-able for optimum sanding.

Features

- Rotating horizontal axes with adjustable speed by electronic inverter

- Pressure rollers loaded with springs that ensure the sealing of workpieces during transport

- Motorized roller conveyor with variable speed via inverter

- Easily removable and interchangeable axes

-

Manual inclination of all axes

- Roll feed or carpet of choice

- Full width pressure rollers easily adjust by hand crank to hold the work pieces firmly on the power roller conveyor and against the guide fence.

Advantages

- Advantages

- Reduced dimensions

- Quality-price ratio of maximum convenience

- Modular construction Thanks to the addition of additional work units on all four sides

This configuration is the perfect fit molding sander for the medium to small operation. These machines have it all!

It has variable speed on the driven rollers, running 10-50 feet per minute.

It has 4 hold-down pressure rollers from the top, holding the molding firmly in place while it travels though the machine.

Each spindle has variable speed to change the sanding on the molding for less sanding in sealer and primer coats to more sanding on raw wood.

These machines will remove light knife marks and prep the wood for staining and sealing without being detrimental to the profiles and contours of your work pieces.